LL-41 & LL-41B solutions

LL-41

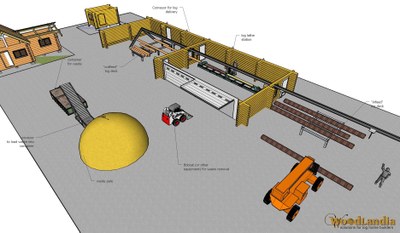

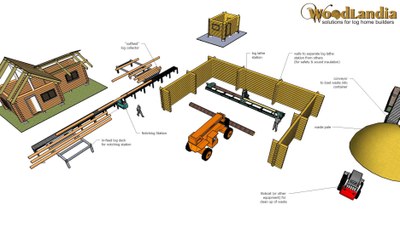

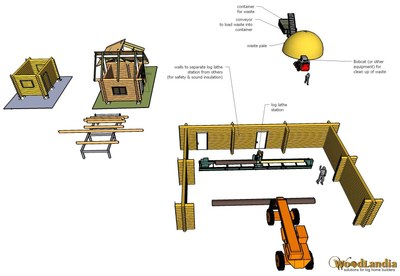

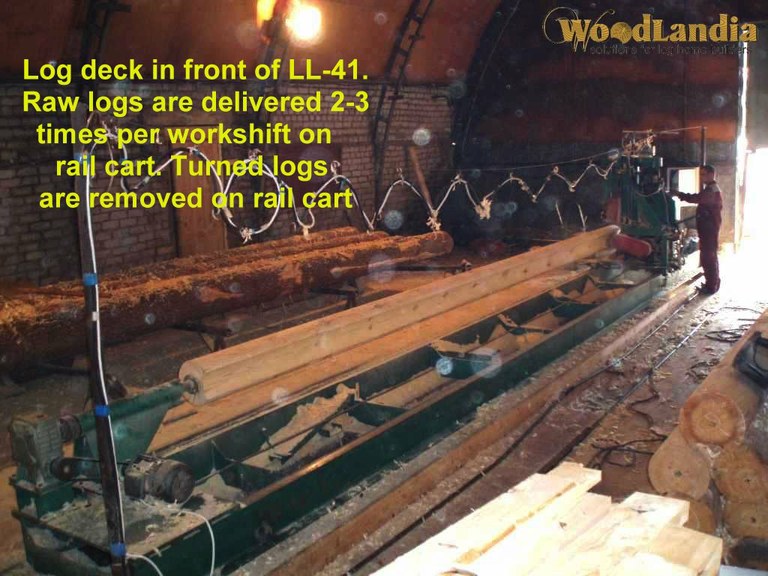

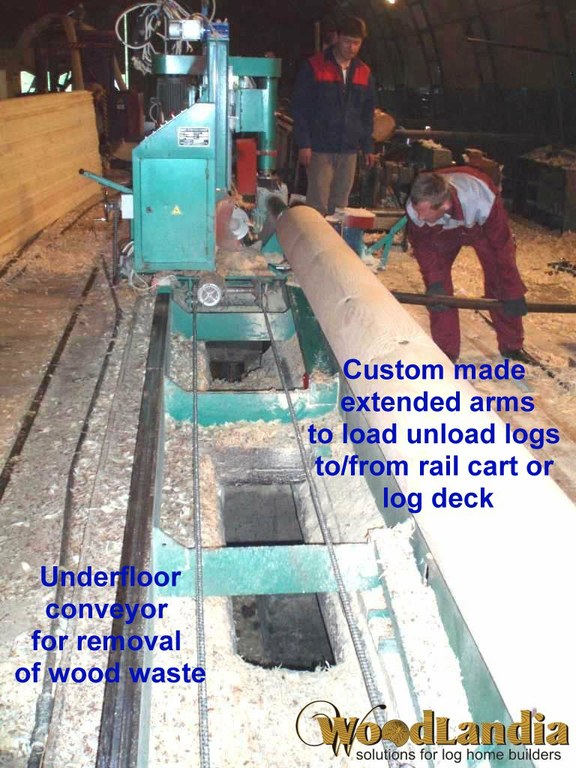

- This is very important to consider how logs will be delivered to the log lathe. Inefficient log transportation will affect productivity of LL-41.

- Although small companies can rely on tractor with forks or all-terrain forklift to deliver and remove logs, bigger companies should think about rail cars, conveyors or roll tables.

- Removal of waste is also important since it may cause delays in work flow process. Consider using of conveyors for waste removal from/under the LL-41. This will benefit productivity of the machine.

Click on picture to see it in full size

|  |

Efficient log transporting and waste removal systems can increase productivity drastically

Click here to jump to the page describing log lathe LL-41.

LL-41 "Real Life" examples in pictures

|

|

|

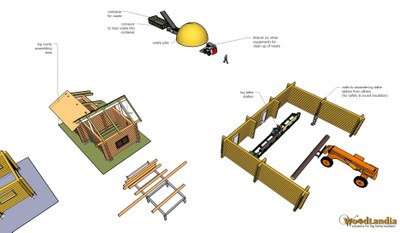

LL-41B

This solution is a bundle where log lathe LL-41 and log notching machine NM-1 work simultaneously. In this solution LL-41 is not required to mill notches. Turned and coped logs are sent to Notching station or to stocking area (or to kiln for example). So notching station can receive log as from LL-41 as well as from the stock. By such way the business can work in different modes.

Other option is that LL-41 is located in one place and notching station in other. For example log lathe can be set up near of logging area and notch-maker can be setup at building site. Logs turned on the log lathe are sent to building site. So notches will be milled just before logs to be put onto the log shell. Such configuration can safe significant amount of transportation expenses in some particular circumstances.

Click here to jump to the page describing NM-1 log nothing machine

Click here to jump to the page describing NM-2 log nothing machine

Click here to jump to the page describing NM-3 log nothing machine